Introduction to High-Frequency PCB Materials

In the PCB manufacturing industry, we know that speed, signal integrity, and reliability aren’t just goals—they’re requirements. In high-frequency PCB applications, from 5G infrastructure and radar systems to medical imaging and automotive ADAS, the right material for high-frequency doesn’t just affect performance—it defines it.

For years, FR4 has been the reliable, go-to material for everyday electronics and standard boards. But when you’re pushing into the high-frequency realm, conventional materials like FR4 can fall short. That’s why, at LHD TECH, we turn to advanced solutions like Rogers® materials for projects where signal loss, thermal management, and consistent dielectric properties are non-negotiable.

Rogers PCBs are built for speed. They’re engineered for high-frequency situations where even small details—like the material’s dielectric constant (Dk) and loss factor (Df)—make or break performance. Whether you’re working on millimeter-wave comms, aerospace radar, or next-level automotive safety systems, we’ll help you choose and apply the right Rogers PCB material so your project doesn’t just function—it performs brilliantly.

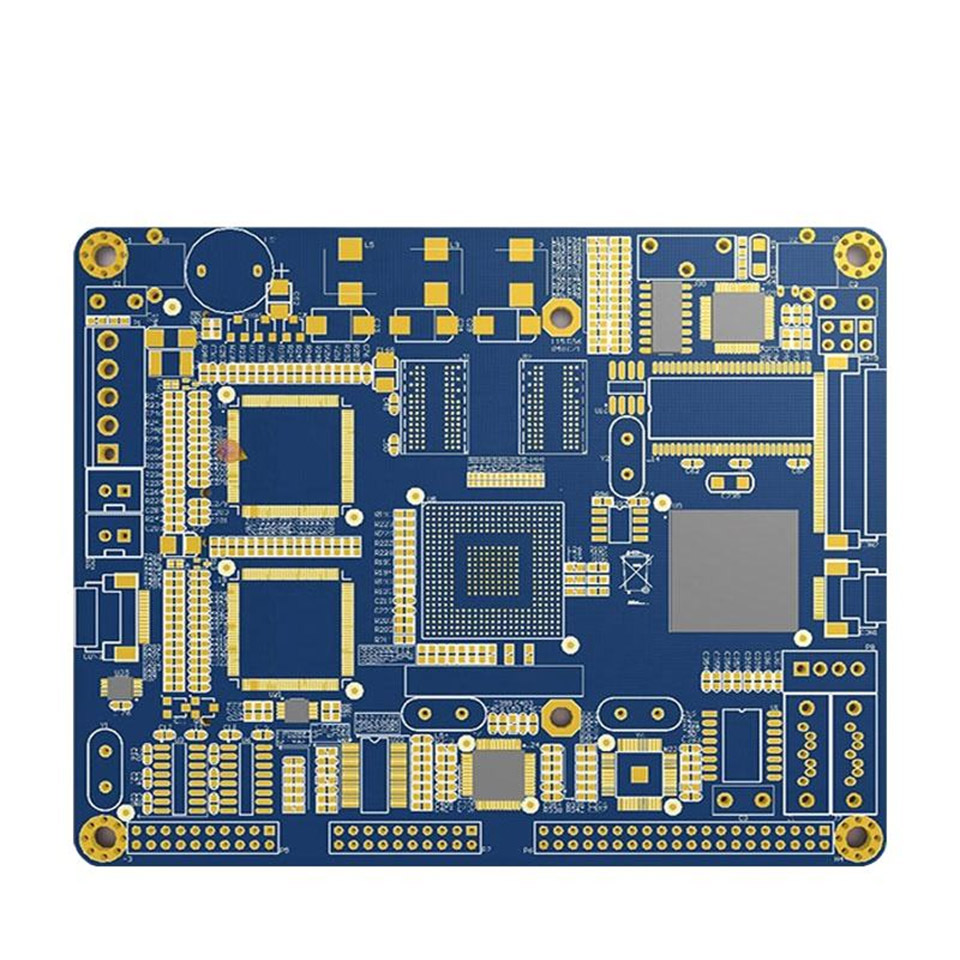

What is a Rogers PCB?

Put simply, a Rogers PCB is built with specialized, high-performance materials made by Rogers Corporation. While standard FR4 material can cause signal loss and behave unpredictably in high-frequency applications circuits, Rogers materials are engineered from the start to perform. They deliver excellent electrical properties, keep signal loss to a minimum, and offer tight dielectric constant control—making them the go-to choice for demanding RF and high-speed digital designs.

Key Features of Rogers PCB Materials

We choose Rogers materials for their uncompromising performance in critical areas:

- They’re built to excel in the high-frequency world—delivering reliable performance from 500 MHz all the way into the GHz range. That makes them ideal for modern RF PCB applications, microwave systems, and millimeter-wave applications.

- Predictable & Stable Dk: The dielectric constant of Rogers PCB materials is not only low but highly consistent—both across a panel and over a range of temperatures. This stability (typically ranging from 2.2 to 10.2 across different grades) is vital for maintaining controlled impedance and signal timing.

- Thanks to an exceptionally low loss tangent—(as low as 0.0013 in some series, and commonly 004 for Rogers boards)—Rogers boards keep your signal transmission strong and clear, even over longer traces. You won’t have to worry about your signal fading or distorting mid-route.

- Thermal & Mechanical Reliability: They’re built tough. With wide operating temperature ranges and stable mechanical properties, these materials perform consistently whether it’s freezing cold or scorching hot.

- And they’re tough, too. With a wide operating temperature range and stable mechanical properties, these boards stay consistent and reliable, whether they’re in a sweltering server rack or a vibrating automotive module.

Common Types of Rogers PCB

Our team has deep experience fabricating with the most popular types of Rogers PCB, including:

- Rogers 4350B(RO4350B): Think of this as our high-performance workhorse. It’s a top-tier ceramic laminate that gives you excellent electrical consistency without breaking the bank—perfect for commercial RF projects.

- Rogers 4003C (RO4003C): This one’s all about rock-solid stability. It delivers outstanding electrical and mechanical performance, making it a popular choice for power amplifiers and antenna systems.

- Rogers 3003(RO3003): When you need ultra-low loss and unwavering signal stability, this ceramic-PTFE composite delivers. It’s the go-to for critical applications in aerospace and high-reliability commercial systems.

- Rogers 4534:This material is built for miniaturization. With its high dielectric constant, it lets us shrink the size of components—ideal for space-tight designs like GPS antennas.

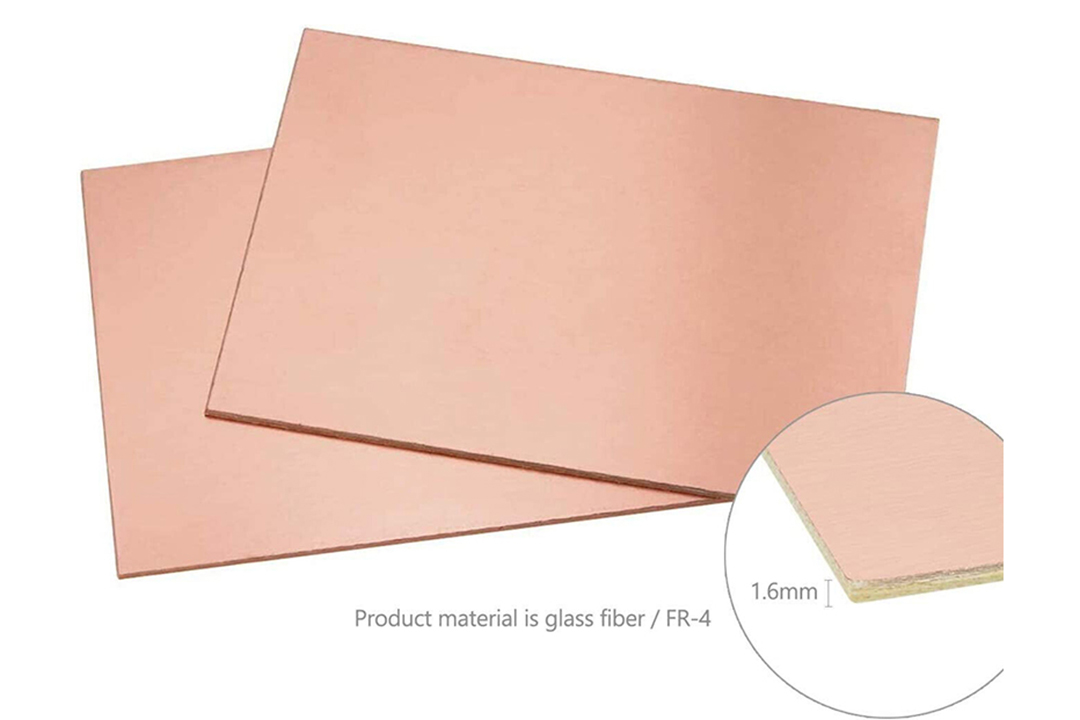

Understanding FR4: The Standard & Its Limits from LHD TECH’s View

At LHD TECH, we understand that the right material is the foundation of every successful PCB. For decades, FR4 has been the industry’s workhorse—a versatile and economical fiberglass-reinforced epoxy laminate that serves as the standard for PCB fabrication in countless applications.

We regularly specify FR4 for designs where cost, manufacturability, and robust mechanical properties are the primary drivers. It’s an excellent choice for consumer electronics, industrial controls, power supplies, and most digital or low-to-mid frequency analog circuits.

Properties of FR4 Material

- Dielectric constant of FR-4:FR4 offers a very low initial cost and is easy to process, drill, and fabricate using standard PCB equipment.

- Loss tangent: It provides reliable rigidity and durability for a wide range of applications.

- Electrical Baseline: FR-4’s dielectric constant usually falls between 4.2 and 4.8—but don’t count on it staying put. It can drift with changes in frequency, temperature, humidity, and even from one batch of material to the next.

Limitations for High-Frequency Applications

That’s why, while FR4 works well for plenty of projects, it starts to struggle in high-frequency applications. And that’s exactly where FR4 and Rogers materials step in to make all the difference.

- High Loss at High Frequencies: FR4’s loss tangent is relatively high (usually over 0.018), so it converts a lot of signal energy into heat. This causes significant signal loss at high frequencies—your signal basically fades before it reaches its destination, hurting overall performance.

- Unstable Dielectric Constant: dielectric constant of FR4 doesn’t stay put—it shifts more than engineered materials. This makes it hard to keep impedance matching difficult, leading to signal reflections, phase issues, and timing errors. For RF, microwave, and high-speed digital designs, these kinds of inconsistencies are a dealbreaker.

Rogers PCB Material Series: Types of Rogers PCB

This range of types of Rogers PCB materials provides us with critical design flexibility. By selecting the right member of this advanced family, we ensure your board delivers peak performance, whether the priority is ultra-low loss, extreme thermal stability, or superior dielectric constant (Dk) control. Choosing the correct material for high-frequency applications is not a minor detail—it is a foundational engineering decision, and Rogers Corporation offers us the precise tools to make it.

Table: Key Types of Rogers PCB Material

| Rogers Series | Dielectric Constant (Dk) | Loss Tangent (Df) | Main Application | Notable Properties |

| RO4000 (e.g., RO4003C, RO4350B) | 3.38–3.66 | 0.0027–0.0037 | RF, 5G, Antennas, Power Amplifiers | FR4-like processing, reliable, low moisture absorption |

| RO3000 (e.g., RO3003) | 3.0–10 | 0.0013–0.0029 | Satellite, Microwave, mmWave | PTFE/ceramic blend, exceptional low loss |

| Rogers 4534 | 3.4 | 0.0037 | Automotive radar | Highly stable for automotive and industrial use |

| Rogers 4003C | 3.38 | 0.0027 | Wireless, network, base station | Flat Dk, processable with FR4 lines |

| RT/Duroid Series | 2.2–10.2 | 0.0009–0.0027 | Aerospace, Defense, Space | Ultimate loss performance, chemical and mechanical strength |

Material Selection: Choosing the Right PCB Material

At LHD TECH, we know choosing the right PCB material isn’t just about specs—it’s a strategic choice. You have to weigh performance, how easy it is to build, and the total cost. It’s not about finding the “best” material on paper, but the smartest one for your specific design and how long it needs to last.

Key Considerations for Choosing Rogers and FR4

We help our clients navigate this choice every day. Here is our practical framework for selecting between these two fundamental material classes:

- Operating Frequency: This is often the primary driver. For consistent performance in high-frequency and RF applications (typically above 1-2 GHz), Rogers materials established industry standard for PCB. FR4’s variable electrical properties become a significant liability at these speeds.

- Total Project Cost:FR4 has a clear advantage in upfront material cost. However, for mission-critical designs, the higher initial cost of Rogers material is an investment. It pays dividends through superior yield, reduced system-level rework, and longer, more reliable operational life in the field—lowering the total cost of ownership.

- Type of application:We follow a clear application-based logic:

- Go with Rogers for: RF and microwave designs, antennas, satellite gear, automotive radar (like ADAS), 5G equipment, and high-speed digital boards.

- Stick with FR4 for: Everyday consumer gadgets, industrial controllers, power circuits, simpler digital boards, and any project where you don’t need top-tier signal performance.

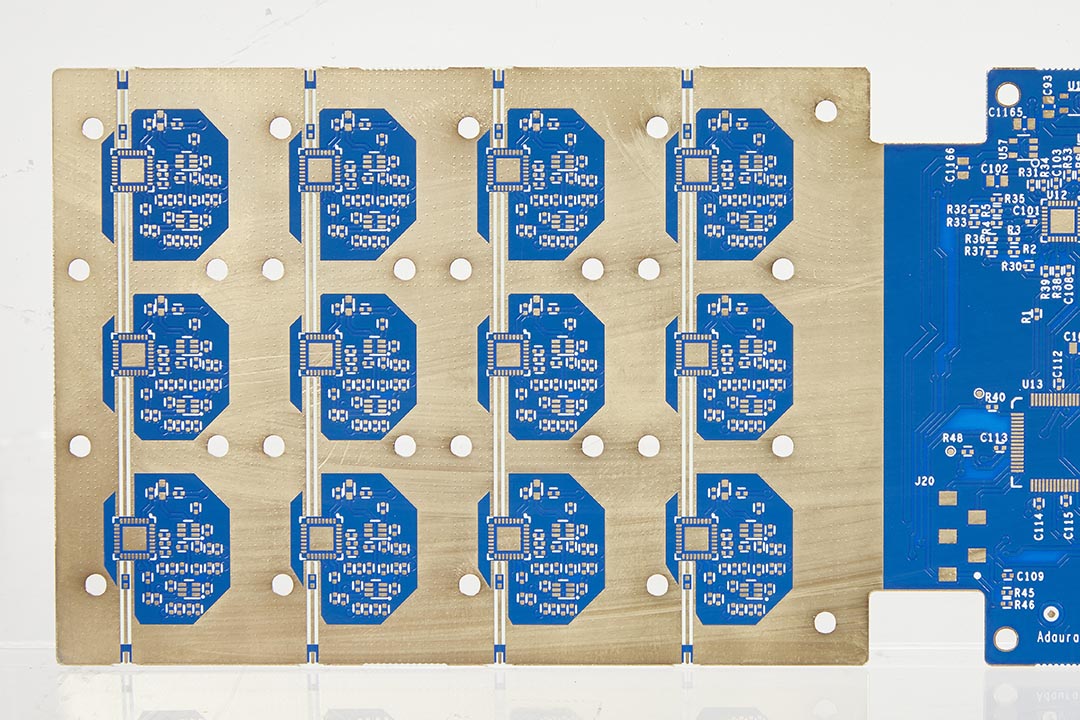

- Layer count:Both materials are fully capable in multilayer and HDI designs. A powerful cost-optimization strategy we employ is the hybrid stack-up. Here, we use Rogers material for the critical, high-speed signal and impedance-controlled layers, while using FR4 for the less sensitive power, ground, and mechanical core layers. This approach delivers Rogers-grade performance where it matters most, at a significantly reduced cost.

PCB Fabrication, Manufacturing, and Assembly

We know that the true potential of any PCB material—be it advanced Rogers PCB and fr4 pcb materials—is only realized through expert pcb fabrication, manufacturing, and assembly. We apply a meticulous, process-driven approach to ensure every board performs as designed.

Our Critical Manufacturing Protocols

Our experience has defined key practices that differentiate a functional board from a reliable, high-performance one:

- Surface prep:Unlike FR4, Rogers materials require specialized surface treatment—such as plasma or chemical etching—prior to lamination or plating. This critical step ensures optimal copper adhesion and prevents delamination, a standard part of our controlled process.

- Precision Drilling & Via Formation: For Rogers PTFE-based and hybrid materials, standard drilling can cause resin smear or tearing. We employ specialized drill regimens and, for HDI designs, laser drilling to create clean microvias and through-holes without compromising the substrate.

- Leading manufacturer of high-performance PCB:We partner directly with Rogers Corporation and operate under the toughest quality standards—like ISO 9001, AS9100 for aerospace, and ISO 13485 for medical devices. This means every board we make starts with genuine Rogers material and stays fully traceable from raw sheet to finished product.

- Compatible Assembly: We select solder masks, pastes, and fluxes specifically engineered for high-performance materials. This prevents common assembly failures like blistering, chemical attack, or thermal delamination during reflow.

- Comprehensive Validation Testing: For critical applications in automotive radar, aerospace, and medical devices, our testing goes beyond continuity. We perform impedance verification (TDR), RF testing (VNA), and rigorous environmental stress testing (thermal cycling, vibration, humidity) to guarantee performance in real-world conditions.

Practical Tips for Board Design Using Rogers and FR4

Ensure Optimal Performance:

- Board design for high-frequency:Effective board design for high-frequency circuits cannot rely on approximations. We insist on simulating with the actual Dk (Dielectric Constant) and Df (Dissipation Factor) values from your specific material batch and supplier. Using generic library values or online calculators introduces risk; we use verified data to predict real-world behavior.

- PCB manufacturing and assembly:True optimization happens when PCB manufacturing and assembly considerations are integrated early. We collaboratively review panel utilization, finalize copper weights for consistent impedance, and lock in the stack-up tolerance stack. If your design benefits from a hybrid stack-up (combining Rogers and FR4), this must be planned from the initial design phase to ensure structural integrity and cost efficiency.

- Material selection for best PCB:Choosing the best PCB material is foundational. Our rule of thumb: for frequencies above 2 GHz, and for applications demanding lower Df (loss) and exceptional phase stability, Rogers materials are typically non-negotiable. Within the Rogers portfolio, series like RO4000 (for cost-effective performance) or RO3000 (for ultra-low loss and stability) are usually the ideal starting points for our analysis.

By partnering with LHD TECH, you integrate this disciplined, front-loaded approach into your development cycle. We don’t just build to print; we co-engineer the entire pathway from simulation to assembly to guarantee your board performs flawlessly.

Conclusion: The Future Standard for PCB

The direction of electronics is clear: everything’s getting faster, more reliable, and smaller. That shift is completely changing how PCBs are designed.FR4 isn’t going away—it’ll still be the go-to, cost-effective choice for everyday applications. But for the cutting edge, the future is all about high-performance engineered materials like Rogers.

For the frontiers of technology—5G infrastructure, aerospace and defense systems, satellite communications, advanced medical imaging, and automotive radar—the standard is already shifting. The higher dielectric constant, lower loss tangent, and engineered reliability of Rogers PCB material and are not merely an advantage; they are becoming a prerequisite for success.

Why Rogers PCB Will Be the Standard for High-Performance PCB

This shift is driven by undeniable engineering benefits that align perfectly with next-generation demands:

- Superior electrical properties: The tightly controlled dielectric constant of Rogers materials, which remains stable across frequencies and temperatures, is non-negotiable for predictable, high-speed signal integrity. This consistency is what makes Rogers the definitive choice for high-frequency applications.

- Lower signal loss: With an extremely low loss tangent (often below 0.004), Rogers laminates preserve signal strength and purity where FR4 would cause significant attenuation. This efficiency is critical for maximizing the range, clarity, and power of RF and microwave systems.

- Mechanical and environmental resilience: Rogers materials offer best-in-class mechanical and environmental resilience, including low moisture absorption and excellent chemical resistance. This inherent ruggedness ensures long-term reliability in harsh, mission-critical operating conditions.

- Compatibility with advanced manufacturing:Rogers technology is fully compatible with the most sophisticated fabrication techniques. Whether your design calls for multi-layer HDI, blind/buried vias, or hybrid stack-ups that intelligently mix Rogers and FR4, these materials facilitate leading-edge PCB manufacturing and assembly without compromise.

At LHD TECH, we are not just observing this future—we are building it. By integrating Rogers PCB technology into our core capabilities, we provide our partners with the foundational material advantage required to lead in the high-performance electronics landscape.