Introduction to Aluminum PCBs

Electronic devices are currently undergoing rapid development. Market demands for thermal management performance continue to rise, while requirements for device reliability and structural robustness are also steadily increasing. Against this trend, aluminum-based printed circuit boards have emerged as a widely recognized and critical solution in the industry. This type of circuit board offers exceptional heat dissipation properties, with its metal-core structure providing distinct advantages.

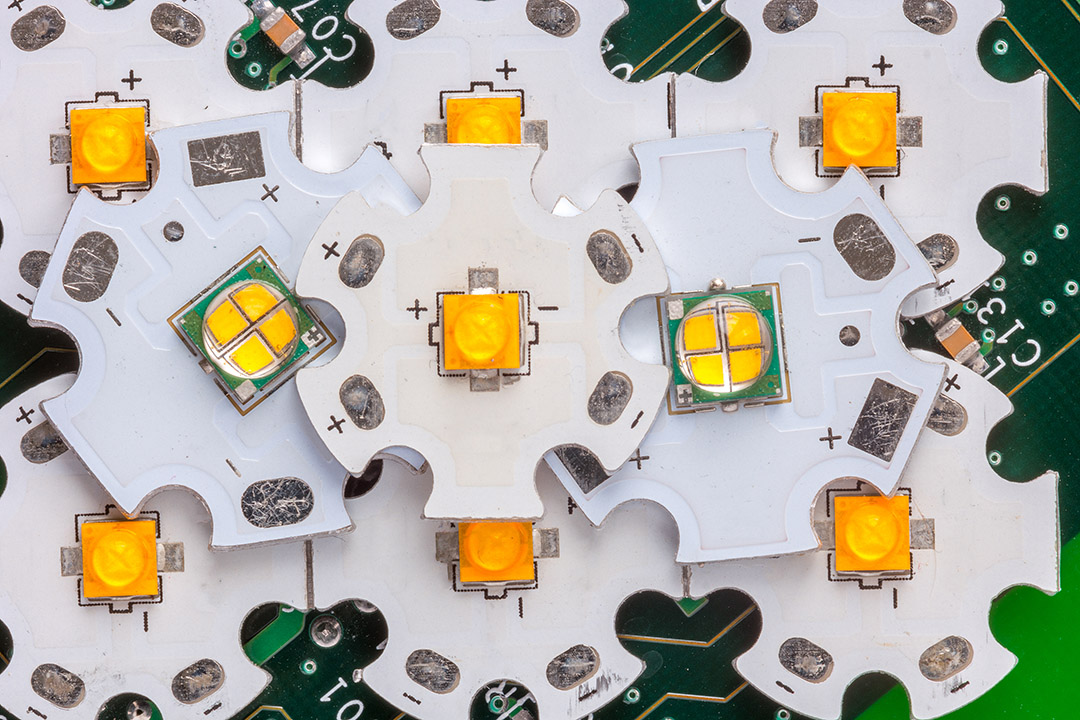

Today, aluminum-based PCBs are successfully utilized in LED lighting systems, play a significant role in automotive power electronics, and have expanded into multiple key industrial sectors such as renewable energy. They have become an essential foundational component in modern electronics manufacturing.

Understanding the Structure of Aluminum Core PCBs

Aluminum substrates are often referred to as metal substrates or MCPCBs. This type of substrate has fundamental structural differences from traditional FR4 circuit boards. FR4 circuit boards use glass fiber laminates as their base material, while aluminum substrates adopt a multi-layer stacked structure design. This structure has been specifically optimized for power bearing capacity, heat dissipation efficiency and mechanical reliability:

Basic Aluminum PCB Stackup

| Layer Name | Key Material | Function |

| Copper Layer | Copper Foil (1-4oz) | Circuit traces and signal paths |

| Dielectric Insulation Layer | Epoxy, polyimide, Al oxide | Isolation & thermal transfer |

| Aluminum Core/Base Layer | Aluminum Alloy (5052, 6061) | Main thermal and mechanical support |

| Solder Mask/Surface Finish | Solder Resistant Epoxy, ENIG, HASL | Protection, identification, solderability |

Structure Tips:

- The aluminum base membrane supports direct and efficient pulling of heat away from hot electronic components.

- The dielectric insulation layer must be thermally conductive yet electrically isolating, optimizing thermal management without risking shorts.

- The aluminum layer further acts as a shield and a path for dimensional stability across temperature cycles, which is critical in high temperature environments.

Why Use LHD TECH’S Aluminum PCB Substrate?

Aluminum PCBs are widely used in core PCB application areas such as lighting systems and power modules. This is attributed to the unique properties of the aluminum PCB substrate material.It demonstrates significantly superior heat dissipation efficiency compared to traditional PCB substrate materials.

LHD TECH’S Advantages of Aluminum as a Substrate:

- High Thermal Conductivity:Aluminum can conduct and distribute heat up to 235 W/mK, far outperforming both FR4 and most ceramics.

- Low Thermal Expansion:Reduces risks in high power and high temperature designs by matching component CTEs (coefficient of thermal expansion).

- Excellent Mechanical Integrity:The metal core lends structure and rigidity, enhancing vibration and impact resistance critical for automotive and industrial circuit boards.

- Electrical Isolation via Dielectric Layer:Essential for safe operation of all core PCBs and power applications.

- Cost-Effective and Recyclable:Aluminum is readily available, less costly than copper, and fully recyclable—making it a sustainable choice for today’s PCB industry.

Aluminum PCB Materials & Stack-Up Explained

Materials in the Aluminum PCB Stackup

- Copper Track Layer: Always select for conductivity, width, and current carrying needs.

- Dielectric: Polyimide or epoxy resin. Polyimide has excellent high-temperature resistance and enhanced chemical stability. Epoxy resin has significant cost advantages and can exhibit good mechanical properties.

- Aluminum Base Layer: Choose 5052 for corrosion resistance/flexibility or 6061 for strength.

- Solder Mask: This material possesses high-temperature resistance. It can achieve a precise coating effect. This precise coating provides a reliability guarantee for the PCB assembly process.

Advanced Stack-Up Options:

- Single Layer Aluminum Boards:For basic LED or power boards.

- Double Layer or Multi-layer Aluminum PCBs:For more complex, high-density circuit boards.

- Hybrid MCPCB Stackups:Integrating FR4 or other specialized layers for added flexibility or signal integrity.

Table: Comparing PCB Stack-Ups

| Stackup Type | Description | Common Use |

| Single Layer Aluminum PCB | 1 Copper, 1 Dielectric, 1 Aluminum Core | LED lamps, power drivers |

| Double Layer | 2 Copper, 2 Dielectric, 1 Aluminum Base | Automotive, converters |

| Multilayer Aluminum PCB | 3+ Copper, Multilayer Dielectric, 1–2 Aluminum Layers | Power BMS, telecom, radar |

LHD TECH’S Manufacturing Process for Aluminum PCBs

Compared with the manufacturing process of standard FR4 circuit boards, the manufacturing process of aluminum PCB circuit boards needs to add several extra processes. The core purpose of these processes is to ensure that the substrate has excellent and stable thermal performance and mechanical properties:

LHD TECH’S Step-by-Step Process:

- Aluminum Preparation: Cleaning, degreasing, and prepping the aluminum base for dielectric lamination.

- Dielectric Lamination: Application and curing of the thermally conductive insulation layer.

- Copper Lamination: Copper foil is pressed and bonded, forming the outer conductive surface.

- PCB Imaging & Etching: Using photoresist and chemical etching to define copper traces for the printed circuit.

- Drilling & PTH Formation(for multilayer): Precision drilling for via holes and plating for electrical interconnection.

- Solder Mask Printing and Surface Finish: Protects copper tracks, enables easy soldering during PCB assembly.

- ROUT and Singulation: Final board outline routing/cutting.

- Inspection & Testing: E-test (electrical), AOI, and visual QC.

Types of Aluminum PCBs and PCB Options

Common PCB Options with Metal Core Technology

- Single Layer Aluminum PCB: Simple, cost-efficient for basic heat dissipation.

- Double Layer Aluminum PCB: More routing room, better for modules integrating both power and control.

- Multilayer Aluminum PCB: Advanced solution for the integration of power and signal paths with ultimate thermal management capability.

- Flexible Aluminum PCBs: Hybrid design combining metal core with flexible layers; ideal for tight spaces in wearables or medical electronics.

Choosing the Right Aluminum PCB Option

When we select among single-layer, double-layer, and multilayer aluminum PCBs, the following factors require comprehensive evaluation:

- Power Dissipation Needs:High power applications with substantial heat loads (LED drivers, power converters, battery management modules) benefit most from double or multilayer aluminum PCB stackups with thicker aluminum base layers and optimized dielectric insulation layers.

- Circuit Complexity:Simple lighting modules often only need single-layer aluminum PCBs. Specific application scenarios include automotive electronics, industrial control, and high-frequency circuits. These scenarios impose clear requirements for signal integrity. They also require the implementation of more complex functional designs. Multi-layer circuit board designs can meet such demands.

- Mechanical Demands:If your printed circuit board must withstand vibration, shock, and thermal cycling (e.g., in automotive or outdoor industrial uses), prioritize core PCBs with reinforced aluminum base materials and consider hybrid metal core PCB stackups for extra mechanical stability.

- Confined Spaces:For small enclosures, flexible aluminum PCBs merge the benefits of a metal core’s heat dissipation with the flexibility of polyimide or advanced dielectric substrates.

Aluminum PCB Thermal Management & Heat Dissipation

Everything about aluminum PCBs ties back to one key benefit: world-class thermal management. The structure of aluminum boards is engineered specifically to carry heat away from sensitive or high-power devices, solving the top failure modes in electronic devices.

How Aluminum Core PCBs Dissipate Heat:

- Direct Thermal Path:Heat generated at the copper layer is conducted vertically through the dielectric insulation layer to the aluminum base layer, then efficiently transferred away.

- Spreading Effect:The aluminum layer also acts as a heat spreader, distributing heat over a larger area, reducing hot spots and improving overall thermal cycle capability.

- Aluminum Clad Design:Sometimes called aluminum clad PCBs, these designs emphasize maximizing the contact between hot components and the aluminum core material.

LHD TECH’S Advantages of Aluminum PCB

Aluminum PCBs have revolutionized the PCB industry by offering unique properties that address critical needs in electronic manufacturing. Here’s what sets them apart:

Our Core Advantages of Aluminum Printed Circuit Boards

- Superior Heat Dissipation:Fast, direct heat transfer prevents overheating in high-power and high-temperature electronic devices.

- High Structural Strength:The metal core adds rigidity—PCB boards are less likely to warp or crack under load, vibration, or rapid temperature change.

- Excellent Electrical Insulation:The optimized dielectric insulation layer provides robust voltage isolation even at thin cross-sections.

- High Thermal Conductivity:Essential for power management and energy efficiency; makes it possible to downsize or eliminate external heat sinks in many designs.

- Mechanical and Vibration Resistance:Outperforms FR4 PCBs in harsh environments like automotive, rail, industrial, and outdoor deployments.

- Dimensional Stability and Reliability:The dimensional change of aluminum cores under heat is predictable and controlled, perfect for precision PCB applications.

- Eco-Friendly and Recyclable:Aluminum materials are widely recycled—good for green electronics initiatives.

Main Applications of Aluminum Printed Circuit Boards

Aluminum PCBs are widely used in modern electronic manufacturing, especially where heat, high current or tough environments are involved. Let’s look at the most common PCB applications.

- LED Lighting: Aluminum PCBs are widely used in the lighting field. Typical application scenarios include road lighting systems, automotive lighting equipment and architectural lighting projects. Furthermore, aluminum PCBs are also suitable for plant growth lamps and smart city lighting system solutions.

- Power Electronics: Battery management systems (BMS), SMPS (switch-mode power supplies), and DC/DC or AC/DC converters.

- Automotive Electronics: Engine control units (ECUs), inverters for hybrid/electric vehicles, radar and motor controllers.

- Industrial Power & Control: Automation modules, high-power motor drives, relay PCB boards and industrial automation.

- Telecom & Networking: 5G power amplifiers, wireless base station power modules and network switching hardware.

- Consumer & Wearable Electronics: High-power amplifiers, gaming consoles, wireless charging boards and foldable/flexible smart devices.

- Medical & Aerospace: Defibrillator boards, diagnostic equipment, avionics controls and instrumentation PCBs for harsh/variable temperature environments.

LHD TECH’S PCB Assembly for Aluminum Boards & Solder Mask Use

Assembly & PCBA Considerations with Aluminum PCBs

- SMT Compatibility:Aluminum PCBs handle automated SMT soldering processes (reflow, wave) much like other core PCBs—just ensure profiles account for the aluminum’s heat sink effect.

- Stencil Selection:Use slightly larger stencil apertures for large thermal pads, and opt for solder pastes formulated for high-reliability metal core assembly.

- Solder Mask Tips:Pick high-temperature/thermally stable solder masks designed for strong adhesion to the aluminum surface, avoiding delamination or color changes during thermal cycling.

- Panelization & Depaneling:Aluminum PCBs require dedicated routing or v-scoring approaches; avoid aggressive shearing to prevent internal microcracks in the aluminum core.

Tips for Designing Aluminum PCBs and Choosing PCB Substrates

Design Best Practices

- Start from a thermal simulation—use PCB design software that models heat flow through each layer of the aluminum and dielectric stackup.

- Use large copper pour areas and direct thermal vias (if multilayer), tying them thermally to the metal core wherever possible.

- Specify base material thicknesses and dielectric properties based on your worst-case thermal loads and required creepage/clearance distances.

- Always validate with your supplier’s DFM (design for manufacturability) guidelines when using aluminum as your metal core substrate.

Choosing PCB Substrates

When deciding on the ideal pcb substrate for your application, weigh the following:

- Thermal Demand:If your design needs to dissipate significant heat, opt for an aluminum PCB substrate or insulated metal substrate. These are especially critical for high-power, high-temperature or continuous-use environments.

- Electrical and Mechanical Requirements:For designs subject to vibration, impact, or frequent temperature fluctuations, the structure of aluminum with its core mechanical stability is preferred.

- Cost and Mass Production:For high-volume, cost-sensitive applications that require moderate heat conduction, FR4 PCBs are still viable. However, with increasing thermal loads, switching to aluminum core PCBs can save costs downstream by reducing failures and minimizing the need for external cooling hardware.

- Flexibility Needs:If your product design requires bends or folds, explore flexible aluminum PCBs or hybrid stack-ups that combine flexible layers with metal core regions for targeted heat management.

How to Choose a PCB Manufacturer for Aluminum PCB

Selecting an appropriate manufacturer for aluminum-based PCBs represents the primary step in quality assurance. This choice directly impacts the realization of product performance. It also serves as the decisive factor in ensuring long-term reliable operation of the product.This selection directly impacts the performance of the circuit boards. It also determines the long-term reliability of the products.

What to Look For:

- Experience with Aluminum and Metal Core PCBs:Not all fabricators can consistently produce high-quality metal core pcbs. Look for experience in manufacturing aluminum pcbs, especially for your particular application.

- Capability in PCB Stack-Ups:Ensure your manufacturer can deliver the aluminum pcb stackup your design requires—be it single layer, double layer, or multilayer aluminum.

- Certifications:ISO9001, UL approval, and RoHS compliance demonstrate best practices and commitment to the environment.

- Advanced Testing:Demand E-test, AOI, and thermal cycling—especially if your devices must operate in tough environments.

- Support for Prototyping & Mass Production:From fast-turn PCB prototyping to high-volume runs, the right partner offers flexibility across the entire PCB industry.

Conclusion: Why Aluminum PCB Are Leading the PCB Industry

In today’s demanding electronic manufacturing environment, aluminum PCBs have become a pillar of reliability, performance, and innovation. Their unique combination of thermal, mechanical, and cost advantages enables breakthroughs in power electronics, LEDs, automotive, renewable energy, and beyond.